Nudura’s ICF systems are built around a set of clever technologies that make them faster to build with, more accurate on site and less wasteful. At Insubloc, we supply blocks that incorporate three core features – Duramax, Durafold and Duralock – so your projects benefit from smarter design right from the first delivery.

Duramax Technology

Duramax refers to Nudura’s larger-format ICF forms. Instead of lots of small units, each block covers more wall area, meaning fewer joints, faster progress and less room for error.

For your projects, that means:

-

Fewer blocks to handle and install for the same wall area

-

Straighter walls with fewer vertical joints to line up

-

Reduced waste and a cleaner, more efficient site

Duramax blocks keep the system simple: fewer components, quicker courses and a noticeable impact on build speed, especially on larger elevations.

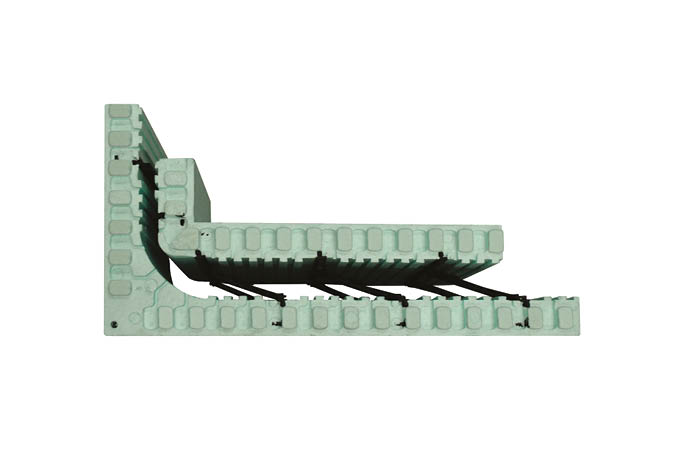

Durafold Technology

Durafold is the folding form design that allows blocks to be shipped and stored flat, then opened out on site. This has a big impact on logistics and handling.

The benefits are straightforward:

-

Reduced transport volume – more wall area per load, fewer deliveries

-

Easier site storage – flat-packed forms take up less space when space is tight

-

Less damage in transit – blocks are better protected while folded

Once unfolded, the forms lock into their working shape and behave just like standard Nudura blocks, ready to be stacked and filled.

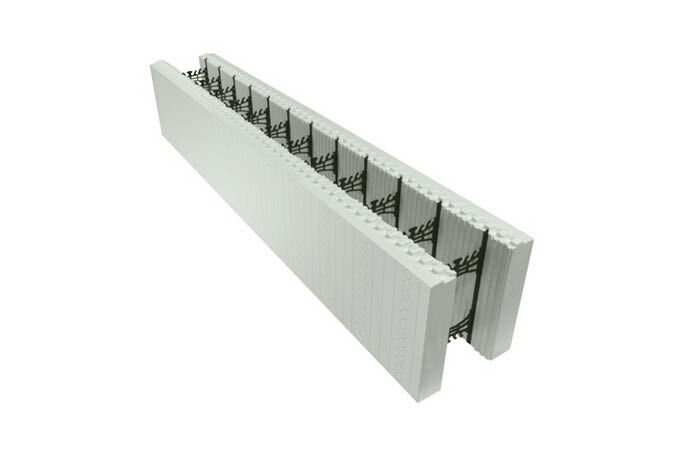

Duralock Technology

Duralock is Nudura’s interlocking system, designed so the blocks key together securely and consistently. The forms interlock on all sides, helping to keep courses aligned and stable before and during the concrete pour.

In practice, Duralock helps to:

-

Maintain clean, straight wall lines as you build

-

Reduce movement and gaps between forms during pours

-

Make block placement more intuitive for site teams

The result is a wall system that feels more like a single, continuous formwork than a collection of separate units, improving both build quality and confidence on site.